DS-3E type Re-spooling machine

1 Usage This machine is applied for layer winding re-spooling of welding wire such as MIG welding wire, stainless wire, aluminum alloy wire, flux cored welding wire, and titanium wire. It is to rewind wire from a metal bobbin onto a plastic spool or wire spool in layer winding forms to provide continuous pay-off for automatic welding.

Classification:

Layer winding machine,Respooling line, Pail packer

Keywords: metal wire products equipment

Contact Us

Product Description

1 Usage

This machine is applied for layer winding re-spooling of welding wire such as MIG welding wire, stainless wire, aluminum alloy wire, flux cored welding wire, and titanium wire.

It is to rewind wire from a metal bobbin onto a plastic spool or wire spool in layer winding forms to provide continuous pay-off for automatic welding.

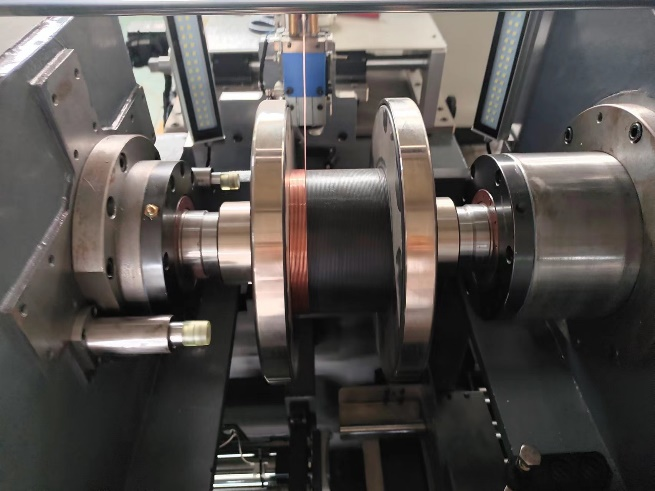

2 Composition

The production line consists of a take-up unit, a pay-off unit, a dancer, and an electrical cabinet.

3 Technical details

|

Technical Item |

Specification |

|

Wire Diameter |

Φ0.8mm-Φ2.0mm |

|

Winding Speed |

Max. winding speed 28m/s, Actual running speed depends on wire diameter, wire roundness quality control, plastic spool quality, and pay-off spool size |

|

Wire straightening device |

Two sets of wire straightening devices are provided, one set for wireΦ1.2mm-Φ2.0mm, another set is for wire diameter Φ2.0mm-Φ3.0mm |

|

Take up main motor power |

11KW synchronous servo motor, brand INOVANCE |

|

Traverse |

Controlled by two servo motors with different directions, Adjustable as different wire diameter Motor power 1KW+0.4KW, motor brand INOVANCE

|

|

Take-up spool clamping |

Clamping & Dis-clamping movement driven by high precision hyperboloid gear reducer, torque adjustable suitable for plastic spool width difference. |

|

Clamping motor power |

2.9KW servo motor, brand INOVNACE |

|

Take-up spool type and size |

Plastic spool Φ300、Φ270 with hole diameter Φ52mm

|

|

Automatic weighting |

The automatic weighting function included an automatic stop at target weight |

|

Tangle error rectifying function |

Automatic testing and recognizing tangle error, automatic stop, automatic unwinding, automatic re-spooling, automatic stop at target weight setting. |

|

Unloading the finished spool function |

Automatic and manual unloading functions are optional For plastic spool type SD270, SD300, automatic unloading is adopted, Automatic push, automatic carrying spool, automatic transport to conveyer, extendable to customer automatic packing and stacking system |

|

Bearing cooling function |

For the take-up main shaft, an oil cooling system is adopted for high-speed running bearing, to enhance the bearing lifetime. |

|

Safety door |

Safety doors are set for all units, doors are forbidden to open while the machine is running at high speed, to ensure operator’s personal safety. |

|

Control system |

Cantilever-type operation panel, with HMI inputting |

|

Take-up unit size |

Length 2000mm× Width1500mm×height1600mm |

|

Production line size |

Length 6700mm×Width2385mm×height1800mm |

|

Conveyor outside length |

800mm |

Previous Page

Previous Page

Related Products

online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.